Biogas from Biomass

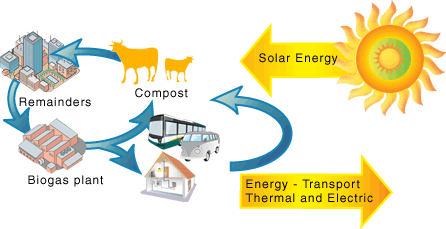

The organic remainders, such as waste, sewage or the excrements that are generated, are generally seen as a problem to get rid of. But this, instead of being a problem, can be turned into an ecological way of getting energy. This idea has been carrying out for years with the so-called biogas. It is a mixture of gas that arises thanks to anaerobic micro organisms that split the organic matter.

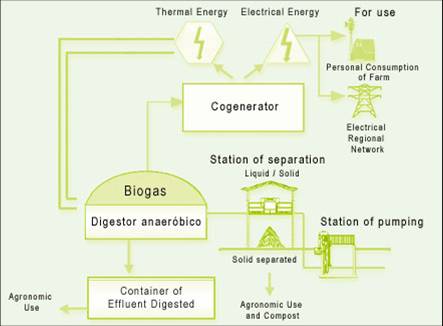

This gas is used commonly in industries, to produce electricity in sewage purification stations in the cities, cattle facilities, the rubbish dumps of urban solid waste and also in rural areas. An interesting matter is that, moreover the remaining solid waste is a good fertilizer for the soil.

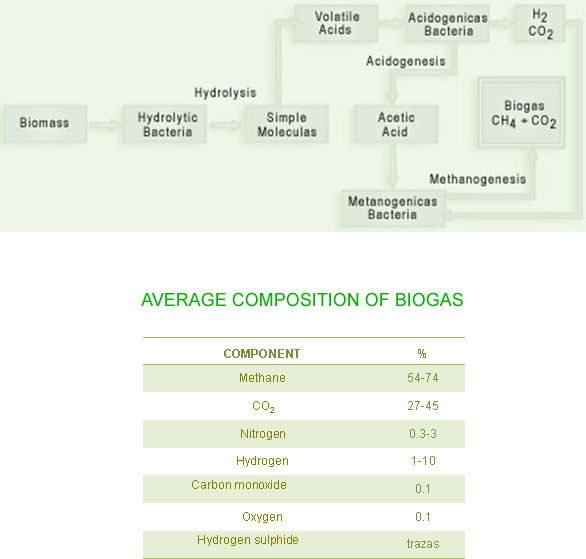

All the organic remainders in general are susceptible to be put under processes of anaerobic degradation. The anaerobic digestion is a biochemical process made in different stages through the action of different types of bacteria. Although strictly several groups of micro-organisms can be distinguished, summarizing and generically speaking, we are going to distinguish two main groups: acid forming and metanogenics.

The process of biomass anaerobic digestion to get biogas consists of the following stages:

- Hydrolysis: Degradation of polymers giving rise to intermediate compounds and fatty acids.

- Acetogenesis: From the previous compounds, they mainly give rise to acetates, H2, CO2.

- Methanogenesis: Obtaining of methane as end item from the decomposition of acetic acid and from the absorption of the H2 released in the oxidation processes.

For each type of substrate and its total degradation it is possible to calculate the theoretical final composition of biogas in agreement with stoichiometry of the reaction. Nevertheless, the real production depends on the obtained level of degradation and it is as well a function of the conditions of process. The most important parameters are: Temperature, pH, C/N ratio, time of retention and present toxic substances.

The process can take place at two levels of temperature. If it is a mesophilic process (approximately 35ºC) the type of fermentation is different from that of a thermophilic process (approximately 50ºC). The pH value must be ranged from 6,2 to 8 since, outside this range, the bacterial action becomes paralyzed. The time of retention will vary depending fundamentally on the type of substrate and the type of digestion. It can oscillate between 10 and 25 days. On the other hand, it is necessary that no toxic substances exist, such as heavy metals, but it is interesting that there exist other nutritious elements in the substrate such as N, P, K, etc. Based on the type of biomass used as raw material, the production of biogas and its methane content varies.